The tire industry has evolved significantly over the years, with advancements in tread technology playing a pivotal role in enhancing safety, performance, and environmental responsibility. Tire treads are more than just grooves—they dictate how a vehicle grips the road, handles varying terrains, and optimizes fuel efficiency.

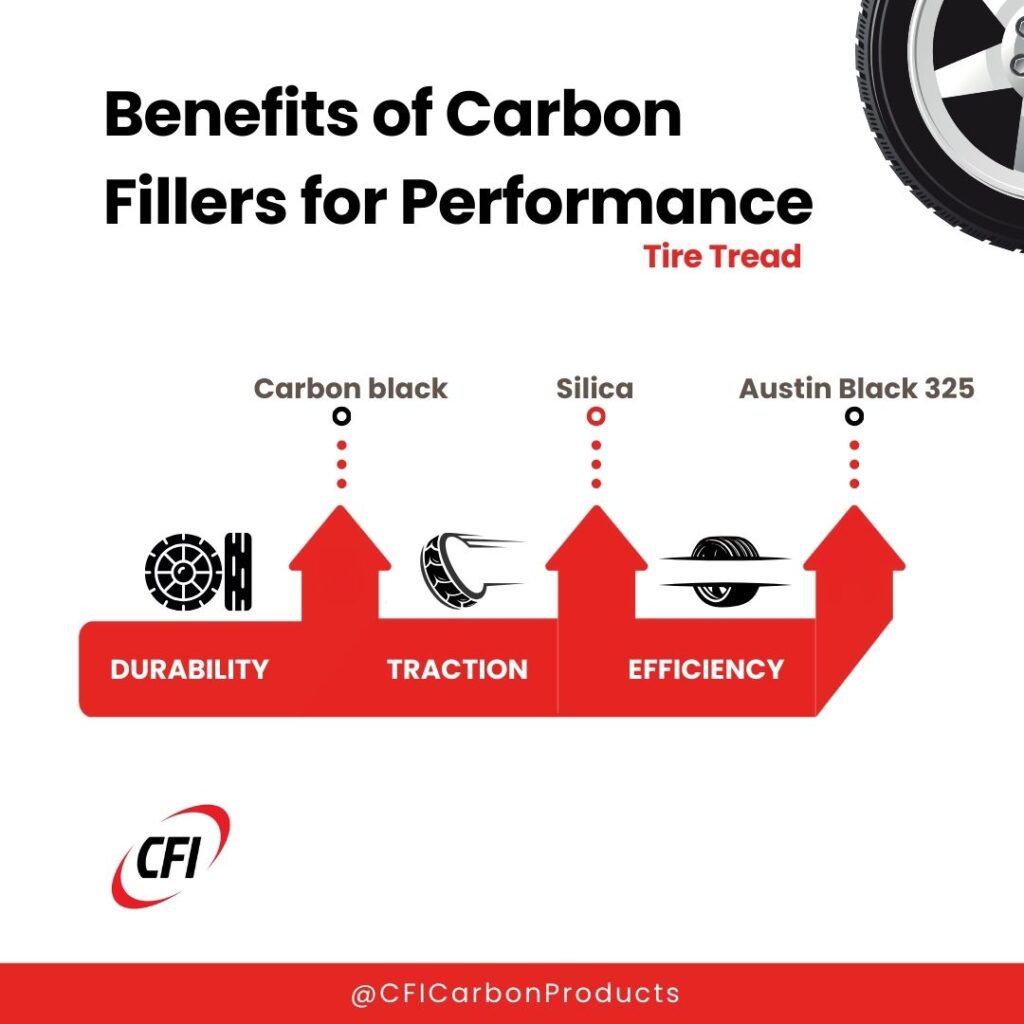

At the core of these advancements lies the material science behind tire treads, particularly the role of fillers like carbon black. Carbon fillers not only enhance tread durability but also contribute to sustainability efforts by improving recyclability and reducing environmental impact.

This article delves into the comparison of modern tire treads, backed by data and insights, to reveal how carbon fillers, including innovative solutions like AB325, are shaping the future of tire manufacturing.

1- The Science Behind Tire Tread Composition

Tire treads are a blend of materials designed to optimize performance, durability, and sustainability. Below is a summary of key components used in tire treads:

| Material | Function | Properties |

| Carbon Black | – Improves strength, durability, and wear resistance | – Adds traction in wet and dry conditions- Enhances tire lifespan- Reduces aging and cracking |

| Silica | – Reduces rolling resistance, enhancing fuel efficiency | – Improves wet traction- Lowers fuel consumption- Can increase cost |

| Alternative Fillers | – Offers eco-friendly options | – Bio-based and sustainable alternatives to carbon black- Can reduce the environmental footprint |

Key Materials Used in Tire Treads

- Carbon Black: A traditional and widely used filler, known for its superior wear resistance, tensile strength, and reinforcement properties.

- Silica: Favoured for its ability to reduce rolling resistance, improve fuel efficiency, and provide excellent wet traction.

- Alternative Fillers: These include bio-based and reclaimed materials designed to enhance sustainability while maintaining performance.

Comparing Filler Performance

| Property | Carbon Black | Silica | Alternative Fillers |

| Wear Resistance | High | Moderate | Moderate |

| Rolling Resistance | Moderate | Low | Variable |

| Wet Traction | Moderate | High | Variable |

| Sustainability Impact | Moderate (fossil-based) | High (sustainable sources) | High (eco-friendly) |

Chemical Insights on Carbon Fillers

Carbon fillers like Austin Black 325 contribute to tire durability by reinforcing the tread, increasing heat resistance, and enhancing overall lifespan. Additionally, their recyclability and compatibility with sustainable rubber blends make them an attractive option for manufacturers aiming to reduce environmental footprints.

These fillers not only meet the demands for performance and longevity but also align with global sustainability goals, ensuring a greener future for tire production.

2-Comparative Analysis: Carbon vs. Silica in Tire Treads

In analyzing the performance of carbon black vs. silica in tire treads, the data clearly shows that these two materials offer different advantages and trade-offs, particularly in areas like wear resistance, fuel efficiency, and environmental impact.

Below is a detailed breakdown comparing the two in a table to highlight the measurable differences:

| Performance Metric | Carbon Black | Silica | Industry Insights |

| Wear Resistance | Moderate (durable but may wear faster under certain conditions) | Superior (due to better heat resistance) | Silica improves tread life in most driving conditions. |

| Fuel Efficiency | Standard (neutral impact on rolling resistance) | Increased by 3-7% (reduces rolling resistance) | Silica is a preferred choice for fuel-efficient tires. |

| Wet Grip | Good (adequate for wet surfaces) | Excellent (superior traction on wet surfaces) | Silica significantly enhances wet grip due to better road contact. |

| Dry Grip | Excellent (strong performance on dry roads) | Good to Excellent (though silica may perform slightly less on dry roads compared to carbon) | Silica provides a reliable dry grip with a slight trade-off. |

| Cost | Lower (more economical in production) | Higher (due to manufacturing complexities) | Silica tends to increase tire costs but offers long-term benefits. |

| Environmental Impact | Higher CO₂ emissions due to increased rolling resistance | Lower (reduced rolling resistance reduces fuel consumption and CO₂ emissions) | Silica helps reduce the overall environmental footprint by lowering emissions. |

| Performance in Extreme Conditions | Good in dry, moderate wet conditions | Better in cold, icy, and wet conditions | Silica improves tire safety under challenging conditions like ice. |

Key Takeaways From This Comparaison in Tire Tread:

- Wear Resistance: Silica provides better heat resistance, which leads to superior performance in terms of wear resistance, contributing to a longer tire life.

- Fuel Efficiency: Silica’s ability to reduce rolling resistance translates directly into better fuel efficiency (3-7% increase), making it the preferred material for energy-efficient tires.

- Grip: Silica excels in wet conditions, offering superior grip and safety in rainy or icy weather, which is why it is often used in high-performance tires.

- Environmental Impact: Silica reduces CO₂ emissions by decreasing rolling resistance, which is a key factor in improving the tire’s overall environmental footprint.

While carbon black has been the traditional choice due to its lower cost, silica is increasingly favored for modern, eco-friendly, and high-performance tires due to its better fuel efficiency, superior grip in wet conditions, and environmental benefits. The shift towards silica is expected to continue, driven by the growing demand for fuel-efficient and sustainable products in the tire industry.

3- Carbon Black’s Role in Sustainability

Reclaimed and recycled carbon black (rCB) plays a significant role in reducing carbon footprints across various industries. By using recycled carbon black, companies can lower their environmental impact, minimize waste, and reduce dependency on petroleum-based materials.

Key Benefits of Recycled Carbon Black (rCB):

- Reduction of Carbon Emissions: The use of rCB in applications like tires, rubber, and plastics helps decrease carbon dioxide emissions compared to conventional carbon black production, which typically requires energy-intensive processes.

- Cost Efficiency: rCB is more cost-effective than virgin carbon black, making it an attractive option for industries under pressure to reduce costs amidst fluctuating raw material prices.

- Durability and Performance: Research shows that when incorporated into rubber and tire products, rCB can offer comparable or even enhanced performance in terms of durability and strength.

Case Studies and Industry Examples:

- Automotive and Tires: The tire industry has increasingly adopted rCB as a reinforcing agent, helping brands like Michelin and Bridgestone meet their sustainability goals. Notably, recycled carbon black is being used to improve the performance of rubber compounds while contributing to the reduction of waste and environmental degradation.

- Plastic and Sportswear: Other industries such as sportswear and plastic manufacturing are also turning to rCB as an alternative to virgin carbon black, contributing to sustainability and circular economy models. These innovations are gaining traction as part of broader environmental initiatives.

Austin Black 325: Sustainable Advantages Austin Black 325 offers unique benefits as a sustainable filler:

- Lower Carbon Dioxide Emission: By using Austin Black 325, industries can reduce carbon dioxide generation significantly, thanks to its more energy-efficient production methods.

- Enhanced Durability: The inclusion of Austin Black 325 enhances the longevity of products like tires and rubber components.

- Cost-Effective: Its cost-efficiency makes it an ideal alternative for companies aiming to meet both environmental and economic goals.

Through these advancements, the use of recycled and reclaimed carbon black, particularly options like Austin Black 325, is making a measurable difference in sustainability efforts across industries.

4- Market Trends and Data Insights: Tire Tread

The global tire material market is seeing significant shifts, with a clear trend toward eco-friendly solutions growing at a compound annual growth rate (CAGR) of approximately 7.8%.

This growth is largely driven by the demand for sustainable materials and green tire technologies, especially in regions like India and globally in the automotive sector.

The market for tire recycling is also expanding, with a CAGR of around 4%, reflecting the push for circular economy models and the reuse of reclaimed rubber in various automotive and industrial sectors.

The adoption of sustainable fillers, such as Austin Black 325, is on the rise in high-performance tires, as manufacturers seek to improve the overall environmental impact of their products without compromising on performance

The growth of green tires is particularly notable in the context of electric vehicles (EVs), where reducing rolling resistance is crucial for enhancing energy efficiency.

Here’s a brief overview of market trends:

| Trend Category | Key Insights |

| Eco-friendly Materials | Growth in sustainable tire materials at a CAGR of 7.8%. |

| Tire Recycling | Expanding at a 4% CAGR, driven by circular economy initiatives. |

| Reclaimed Rubber | Increased use in both automotive and industrial sectors. |

| Sustainable Fillers | Rising adoption of Austin Black 325 in high-performance tires. |

This reflects a broader trend toward sustainability in the tire industry, aligning with regulatory demands and consumer preferences for environmentally friendly products.

5- Practical Applications and Case Studies

Austin Black 325 in Premium Tire Treads

- Austin Black 325 has been adopted in various premium tire brands for its cost-efficiency, durability, and eco-friendly properties.

- Manufacturers have reported improved wear resistance, enhanced traction, and lower rolling resistance, contributing to better fuel economy and extended tire life.

Comparative Analysis: Austin Black 325 vs. Silica-Based Fillers

| Feature | Austin Black 325 | Silica-Based Fillers |

| Cost | Lower initial cost | Higher initial cost |

| Sustainability | Made from reclaimed carbon black, reducing CO2 emissions | Typically requires more energy in production |

| Performance | Excellent durability, traction, and wear resistance | Superior wet grip but higher rolling resistance |

| Environmental Impact | More eco-friendly, reduces landfill waste | Increases fuel efficiency but has a higher carbon footprint during production |

Feedback from Manufacturers

Manufacturers integrating Austin Black 325 have praised its ability to reduce costs without sacrificing performance. It has become a preferred choice for eco-conscious producers aiming to meet industry sustainability targets while maintaining high tire performance standards.

6- Conclusion: Future of Tire Manufacturing

Key Takeaways From The Article:

- Carbon fillers like Austin Black 325 enhance tire performance, improve durability, and reduce environmental impact.

- Sustainable fillers are critical for manufacturers who want to stay competitive in a market increasingly driven by eco-consciousness and regulatory pressures.

Sourcing Decisions For Tire Tread:

- Choosing sustainable materials like Austin Black 325 supports global sustainability goals and meets growing consumer demand for high-performance, eco-friendly tires.

- Manufacturers prioritizing environmentally friendly fillers will likely be well-positioned in the evolving tire market.

Manufacturers can stay ahead in an increasingly competitive and environmentally conscious industry by focusing on informed sourcing decisions and leveraging innovative materials.