Polymer Additives, also known as Plastic fillers, are integral to enhancing material properties and optimizing costs in various plastic applications. With the increasing demand for lightweight, durable, and sustainable materials, the filler market is evolving rapidly, offering advanced solutions across industries such as automotive, construction, packaging, and electronics.

This guide provides a comprehensive view of the applications, types, and benefits of plastic fillers, alongside insights into emerging trends.

What Are Plastic Fillers?

Plastic fillers are additives used to modify the physical, mechanical, and thermal properties of plastic materials. They play a dual role:

- Functional Enhancement: Improving characteristics such as strength, thermal resistance, or conductivity.

- Cost Optimization: Reducing material costs by replacing a portion of the polymer with less expensive substances.

Fillers range from naturally occurring minerals to synthetically produced compounds and are available in forms like powders, fibers, and granules.

Types of Plastic Fillers & Their Applications

The following table highlights common types of plastic fillers, their characteristics, and applications:

| Filler Type | Key Characteristics | Applications |

| Calcium Carbonate | High rigidity, affordability | Packaging, construction materials, automotive components |

| Talc | Improved thermal resistance and dimensional stability | Automotive interiors, appliances, and building panels |

| Kaolin | Enhanced opacity and smoothness | Paints, coatings, and packaging films |

| Glass Fibers | Exceptional tensile strength and durability | Aerospace, automotive, and construction |

| Carbon Black | Electrical conductivity and UV protection | Electrical components, rubber, and automotive parts |

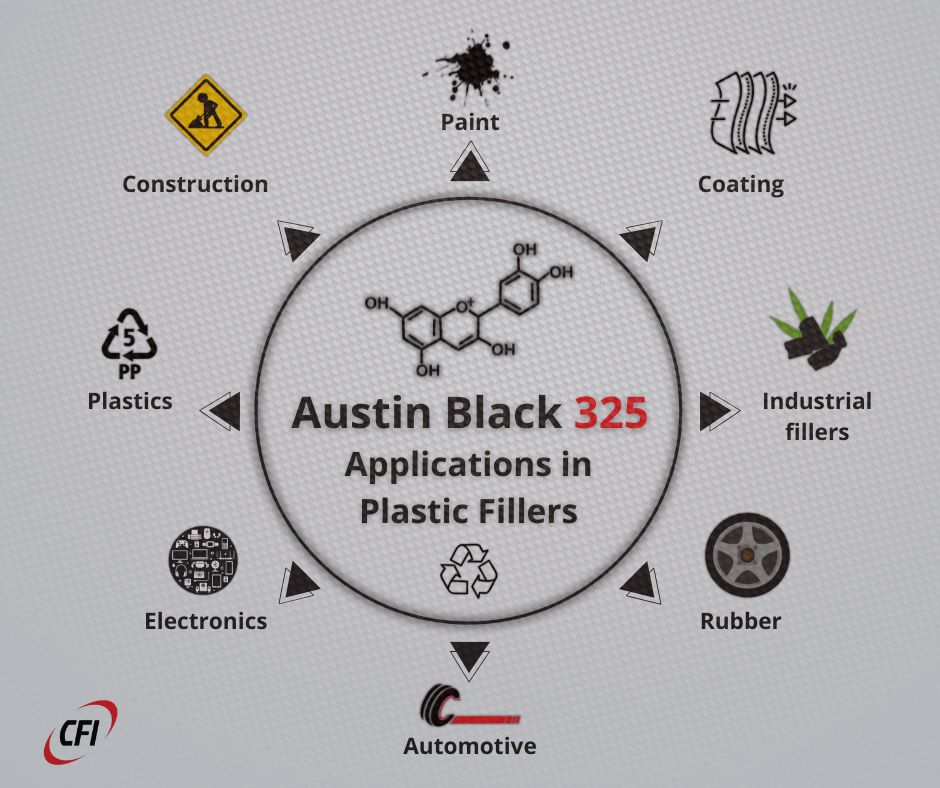

| Austin Black 325 | A form of carbon black offering thermal stability | Used in thermoplastics, coatings, and other engineered plastics |

| Nanofillers | Increased surface area, improved reinforcement | High-performance electronics, medical devices, and automotive |

| Wood Flour | Biodegradability and aesthetic appeal | Eco-friendly packaging and composite decking |

The Advantages of Plastic Fillers in Industry Applications:

Plastic fillers offer several advantages:

- Mechanical Strength: Reinforce plastics to withstand higher loads. For example, glass fibers are widely used in automotive structural components to enhance strength without increasing weight.

- Thermal and Electrical Properties: Fillers like talc and carbon black improve thermal resistance and conductivity, making them essential for electronics and electrical applications.

- Cost Efficiency: Materials like calcium carbonate lower the cost of production while maintaining acceptable mechanical properties.

- Sustainability: Many fillers, including bio-fillers and recycled materials, contribute to reducing the carbon footprint of plastic production.

Industry Applications and Market Trends: Plastic Fillers Across Sectors

Plastic fillers play a transformative role across various industries by enhancing material properties, optimizing costs, and enabling innovative applications.

Below is an industry-by-industry breakdown with key numbers & trends:

Plastic Fillers in the Automotive Sector:

- Applications: Plastic fillers like talc, carbon black, and glass fibers are vital in producing lightweight parts, including bumpers, dashboards, and tires.

- Tires: Carbon black, which makes up 30% of tire weight, enhances durability and heat dissipation. The global carbon black market for tires was valued at $19.6 billion in 2023.

- Electric Vehicles (EVs): Nanofillers, such as graphene and carbon nanotubes, are used in battery casings and lightweight frames, increasing thermal conductivity and strength.

- Market Trend: Lightweight materials save 40% more fuel in vehicles, making fillers critical in meeting global emission regulations.

Plastic Fillers in the Rubber Industry:

- Applications: Carbon black is indispensable in producing durable rubber products, including hoses, belts, and seals, especially in high-wear environments.

- In 2022, over 12.5 million metric tons of carbon black were used globally, with 70% directed at rubber products.

- Silica fillers are gaining traction in high-performance tires, enhancing rolling efficiency and reducing CO2 emissions.

- Economic Impact: The shift to silica fillers in premium tire markets (like Michelin’s Green Tires) accounts for $3 billion annually.

Plastic Fillers in Plastics Manufacturing:

- Applications: Talc, calcium carbonate, and glass fibers improve stiffness and thermal resistance in packaging, consumer goods, and engineering plastics.

- Talc-filled polypropylene is dominant in food packaging and automotive parts, accounting for 30% of global talc consumption.

- Calcium carbonate fillers, the most widely used, reduce costs by 15%-20% per ton of plastic. In 2023, its market size reached $29.3 billion.

- Sustainability Focus: The industry is shifting toward natural fillers, like hemp and cellulose fibers, particularly in bioplastics, projected to grow to $18 billion by 2027.

Plastic Fillers in the Silicon Sector:

- Applications: Quartz and glass beads are widely used as fillers in silicone elastomers for applications like:

- Automotive Seals and Gaskets: Ensuring durability in high-temperature environments.

- Electronics: Silicones with boron nitride fillers are used for thermal management in semiconductors, valued at $450 million globally in 2023.

- Market Trend: Nanofillers such as boron nitride are in demand for lightweight composites in medical devices and electronics.

Plastic Fillers in Coatings and Paints:

- Applications: Fillers improve texture, and durability, and reduce production costs.

- Calcium Carbonate and Talc: Widely used in decorative paints and industrial coatings, accounting for 30% of total production costs.

- Functional Fillers: Zinc oxide and carbon black add UV resistance and corrosion protection, particularly in marine and automotive paints.

- Economic Data: The coatings market using fillers was valued at $160 billion in 2023, with the demand for functional coatings growing by 4.3% annually.

Table: Plastic Filler Applications Across Sectors

| Industry | Sector | Fillers Used | Applications | Key Statistics |

| Automotive | Tires, interiors, EV components | Talc, carbon black, nanofillers, glass fibers | Tires, bumpers, dashboards, batteries | Carbon black market for tires: $19.6 billion (2023) |

| Rubber | Tires, industrial rubber goods | Carbon black, silica, calcium carbonate | Hoses, belts, seals | 70% of carbon black consumption in rubber production |

| Plastics | Packaging, consumer goods | Talc, calcium carbonate, glass fibers, bio-fillers | Food packaging, electronics | Calcium carbonate market: $29.3 billion (2023) |

| Silicon | Electronics, gaskets, adhesives | Quartz, glass beads, boron nitride | Semiconductors, thermal management | Boron nitride market: $450 million (2023) |

| Coatings | Paints, industrial coatings | Calcium carbonate, talc, carbon black, zinc oxide | UV-resistant paints, marine coatings | Coatings market: $160 billion (2023) |

Plastic Filler Trends Driving the Future (2025 & Beyond)

- Sustainability: Increased use of natural fillers aligns with stricter environmental regulations.

- Nanotechnology: Rising demand for nanofillers in high-performance and lightweight applications.

- Specialized Functionalities: Use of conductive fillers like carbon black and graphene for electronics and EVs.

- Advanced Manufacturing Techniques: Additive manufacturing (3D printing) incorporates fillers like glass fibers and nanofillers to create lightweight and strong components.

Plastic Filler Industry Challenges and Solutions

Regulatory Pressure

Stringent regulations, particularly in Europe and North America, focus on reducing plastic waste and promoting sustainability.

The solution lies in adopting bio-fillers and recycled materials to align with these standards.

Raw Material Costs

Price fluctuations in minerals and synthetics can impact filler affordability. Diversifying sources and investing in local production facilities can mitigate cost-related challenges.

Performance vs. Cost Trade-off

Maintaining a balance between performance and cost is critical. Focusing on multi-functional fillers, such as our Austin Black 325, which combines thermal stability and cost-effectiveness, can help achieve this balance.

Plastic Filler Market Insights for 2025 & Beyond

The global market for plastic fillers is projected to grow at a CAGR of 4-6% through 2030, driven by advancements in filler technologies and their widespread adoption in emerging markets. Key growth areas include:

- Asia-Pacific: The construction and automotive boom in countries like China and India.

- Europe: Increased use of recycled fillers due to strict environmental norms.

- North America: Demand for high-performance materials in the automotive and aerospace sectors.

Future Outlook

Plastic fillers will remain a cornerstone of material innovation, bridging the gap between performance and sustainability.

Continuous advancements, such as the development of hybrid fillers combining properties of multiple materials, are set to redefine the industry.

By strategically integrating fillers like Austin Black 325 and nanofillers, manufacturers can deliver superior products while optimizing costs and meeting environmental goals.