When we talk about insulation, we divide it into two categories: thermal and electrical insulation. The difference comes down to what they prevent from passing through a material.

Thermal insulation impedes heat transfers, i.e. conduction, convection, or radiation, and maintains temperatures in buildings, appliances, and industrial processes. A common everyday example is a thermos bottle keeping drinks hot or cold.

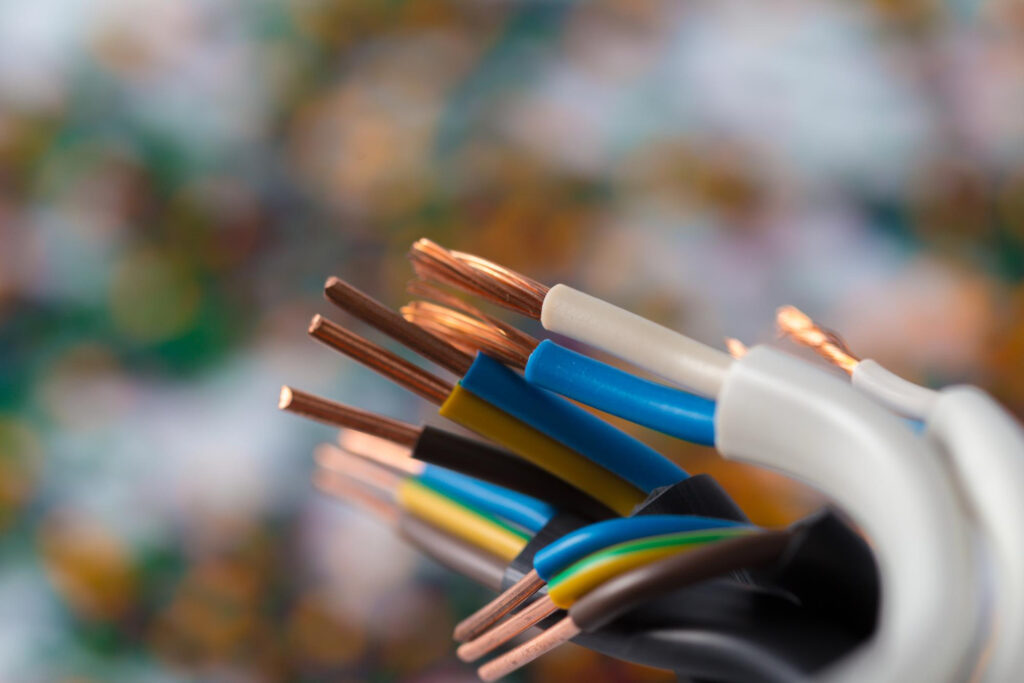

Electrical insulation prevents electric current from flowing through a material. We may have noticed objects like rubber or plastic used to insulate wires, electrical circuits, and power systems to avoid short circuits and shocks and keep electricity from escaping.

So, is carbon a good insulator? We’ll answer this question keeping both classifications in mind.

Is Carbon A Good Insulator?

To answer the question, “Is carbon fiber a good insulator?”, we must first understand its properties and how it’s made.

Whether carbon fiber is a good thermal or electrical insulator depends on its form and treatment. Advancements in technology have enabled us to extract many of its advantages.

Is Carbon Fiber A Good Heat Insulator?

High thermal conductivity is essential for electronics so excess heat is dissipated to ensure component longevity.

However, thermal insulation ensures heat retention. Home construction companies often employ thermal insulators to keep residences pleasant.

Organic carbon fiber’s structure provides higher thermal resistance than thermal insulation. This means it doesn’t attract heat but makes efficient heat transfer easier. It thus offers extraordinary protection against extreme heat.

Insulation can increase with certain composites, so much so that it can be compared to fiberglass or foam. For instance, phenolic resin is added to carbon fiber to make insulation boards and carbon fiber felt.

So, when it comes to thermal conductivity, carbon fiber composites vary. Manufacturers can use inherent physical and chemical properties and add elements to manipulate conduction depending on the needs.

Another important related property is the coefficient of thermal expansion. This measures the change in object size or its expansion or contraction due to a temperature change.

Engineers use this to analyze product transformation with varying temperatures. Generally, carbon fibers in the axial plane will have a negative coefficient of thermal expansion and slightly positive in the transverse direction.

The low coefficient of thermal expansion means that heat will shrink the material. The property facilitates the integration of composite substances that expand when heated.

Carbon fiber is strong and lightweight, and its negative or low coefficient value benefits many applications.

Does Carbon Conduct Electricity?

Carbon fiber is naturally a great electrical conductor.

However, since it’s usually reinforced, its conductivity depends on several factors, such as fiber type, structural orientation, and resin and carbon content in composites.

Why Carbon Fiber Is Preferred In Many Industrial Applications

Carbon fiber has useful properties that make it ideal for manufacturing. Here are the four categories it excels in:

Physical Properties

The density of carbon fiber is low and lies somewhere in this range: 1.60 to 2.00 g/cm³. This makes it useful in industries where lightweight and strong components are necessary for the best performance.

Car bodies, wind turbine blades, sports equipment, and aircraft components often use carbon fiber composites.

Chemical Properties

High chemical stability makes carbon fiber composites corrosion and rust-resistant, and, therefore, highly prized in environments where harsh chemicals or moisture can damage components.

Electrical Performance

Since certain types of carbon fiber are electrical insulators, their uses extend to the aerospace, electrical, and energy sectors. Specialized manufacturing processes help diminish or eliminate electrical conductivity.

Mechanical Properties

Carbon fiber is strong, rigid, stiff, lightweight, and adaptable to strong external forces. Its high tensile strength ranges from 2900 MPa to 7000 MPa ensuring it doesn’t deform or break under excessive pressure.

Where Carbon Fibers Are Used

Carbon fiber’s strength, durability, and flexibility make it attractive for numerous businesses. Here are a few industries where it dominates:

Aerospace

Carbon fibers are one of the aircraft’s structural and electronic equipment components since they’re tough and lightweight. This versatility improves performance and enhances safety.

Electrical Components And Electronics

They’re used for insulating wires and cables. Good insulation prevents electric current leaks and danger.

Energy

They’re lightweight and robust, making clean energy products reliable, durable, and efficient.

Carbon fiber strengthens wind blades, makes vehicles lighter, and is used to manufacture trailers and vessels to carry clean energy. It’s also waterproof and weather-resistant, enhancing longevity and reducing functional costs.

Other than that, carbon fiber composites can be used in construction, automotive, and sports. For instance, thermal insulation in concrete and bricks can make homes more energy-efficient and comfortable.

How Carbon Fiber Insulation Materials Are Prepared

The first step is to select and pretreat the raw materials keeping in mind purity and strength. The common ones are pith, rayon, and polyacrylonitrile or PAN. PAN is often used in carbon fibers exploited in aerospace and other industries due to its great mechanical properties.

PAN is disintegrated with a solvent, giving you a viscous liquid. Further processing will transform this into continuous filaments.

These filaments are baked in the oven at 200 to 300 degrees Celsius after which heat manipulation at 1000 to 3000 degrees Celsius in an inert atmosphere removes non-carbon elements.

Its high-temperature tolerance of 3000 degrees Celsius in inert conditions renders it ideal for high-heat settings.

Pretreatment is necessary to activate active groups, clean impurities, and strengthen binding with the resin. For instance, oxidation increases hydroxyl groups on the surface.

Molding

Equal quantities of resin and carbon fiber are mixed to bind carbon fiber and mold it in adjusted pressure and temperature conditions for a specific time. It involves shaping and curing carbon fiber-based materials into insulation products.

Other elements, such as silica nanoparticles, may be added to reduce thermal conductivity.

The process creates lightweight and rigid products for aerospace, automotive, and industrial applications.

Several molding processes exist such as:

Pultrusion

Pultrusion is a continuous manufacturing process for strong, lightweight composite materials with a constant cross-sectional shape like pipes and rods.

Autoclave Molding

Autoclave molding is a high-pressure, high-temperature manufacturing process to produce high-performance composite materials.

It involves placing reinforced carbon fiber into a mold, vacuum-sealing it, and curing it inside a pressurized autoclave. However, it’s expensive because it takes a long time.

Quality Testing And Control

Strict quality control and testing assesses thermal insulation properties, mechanical strength, dimensional accuracy, and environmental resistance for efficacy and improved performance.

Industries must receive reliable thermal insulation, avoid defects that could lead to operational failure, and meet international safety and performance standards. For instance, high porosity is a flaw that can reduce insulation strength and performance.

Reinforced carbon is heat resistant, a thermal insulator, and lightweight.

Forms Of Carbon Fiber Insulation Materials

Its different forms include flexible carbon fiber insulation, multi-layered carbon fiber insulator, rigid carbon fiber insulation, and composite carbon fiber insulator. Each has a different purpose and therefore serves distinct industries.

Composite Carbon Fiber Insulator

The aerospace industry and nuclear reactors exploit the insulator’s resilience and thermal shock resistance. A ceramic or carbon matrix enhances its insulation capacity.

Rigid Carbon Fiber Insulation

Insulation and endurance favor its use in industrial furnaces and kilns.

Multi-Layered Carbon Fiber Insulators

Several carbon fiber sheets are combined to increase insulation tenfold.

Flexible Carbon Fiber Insulation

This is used in high-heat settings to insulate and seal key components and equipment. Its flexibility and softness make them great in applications where care is required.

What’s Biochar And How’s It Related To Carbon Fiber?

Biochar resembles charcoal and is produced by heating organic materials in a low-oxygen environment.

The process prevents complete combustion, leaving behind a carbon-rich, porous material that’s lightweight with a high surface area and has multiple uses, particularly in soil enhancement and carbon sequestration.

Biochar is a great agricultural component that enhances soil quality, improves water retention, and reduces acidity and nitrous oxide emissions.

It may also be used as a toughening agent in carbon fibers.

Carbon fiber composites are winners in the modern-day economy due to their properties like insulation and tensile strength.

However, we at CFI Carbon Products do things a little differently. With out-of-the-box thinking and problem-solving, our Austin Black 325 offers more to human processes and the environment than carbon black or related compounds. Get in touch to know more.