In our contemporary world, plastics are everywhere, whether we like it or not.

While stuck in traffic, our mind wanders while our eyes absent-mindedly glance at our steering wheel, dashboard, and synthetic car bumpers around us.

We get vaccinated using plastic syringes at hospitals and almost every product in the supermarket is packaged and sealed in plastic.

The telecommunication industry uses these polymers to make cables, circuit boards, and telephones.

And this doesn’t stop there!

They’re here to stay until we find suitable alternatives. But, what are plastic additives? Are they a major ingredient in the industry? Have they revolutionized the way plastics are made?

YES, Plastic Additives Are Important!

Plastics are synthetic polymers, large molecules made of smaller building blocks. But, what are plastic additives?

They’re a complex mix added to the essential polymers to make them more resistant, durable, lightweight, and versatile to fit and transform all applications and processes. This blend is so important that without it plastics would simply not function.

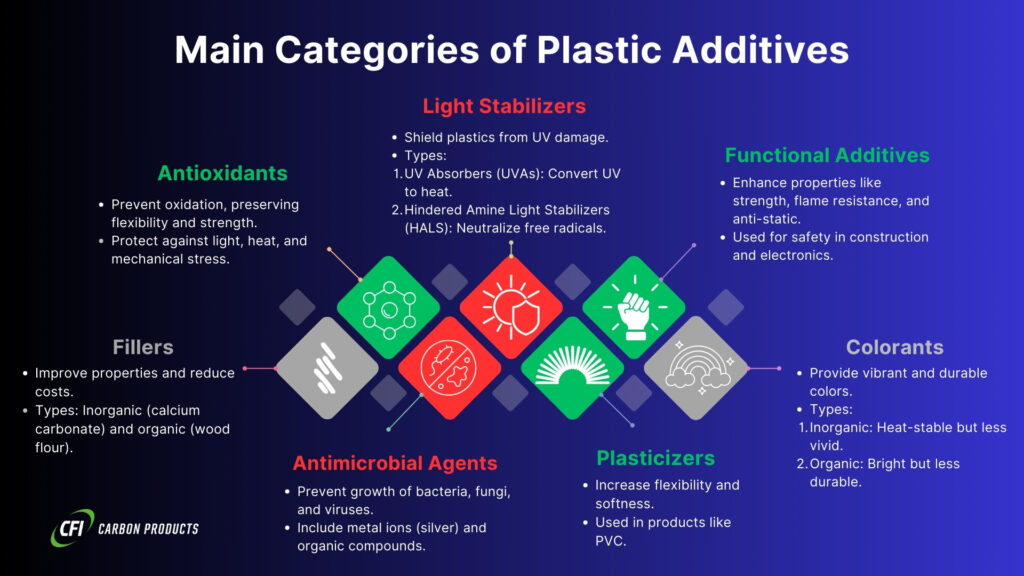

The Main Categories Of Plastic Additives

Research and technology have helped us decrease plastic additive production costs and increase product durability. This plastic additives list helps industries manufacture usable material and achieve market excellence.

- Antioxidants

Polymers are subjected to oxidation reactions throughout their life. Due to oxidation, plastics can change appearance, change viscosities while being processed, or lose mechanical properties like flexibility, tensile strength, impact strength, and elongation.

Antioxidants, as the name suggests, counter this process by containing shifts in molecular weight that cause a loss of essential attributes. They also combat other stresses that can deteriorate the polymer such as mechanical tension, light, and heat.

- Light Stabilizers

UV rays harm plastics because exposure can disintegrate chemical bonds, leading to color changes, cracking, chalking, and a reduction in vital properties like elongation, tensile strength, integrity, durability, and impact strength.

Light stabilizers protect polymers from this impact and other environmental elements like precipitations, contaminants, and temperatures.

Ultraviolet Light Absorbers UVAs or Hindered Amine Light Stabilizers HALS are two additives, each with their peculiarities and benefits.

UVAs absorb harmful rays and release them as thermal energy. HALS react with free radicals that break down the polymer instead of absorbing UV rays. Low HALS concentrations can achieve spectacular results and they’re not consumed.

- Functional Additives

Functional additives provide specific strengths to plastic products depending on their objectives. For instance, industries favor mechanical strength, brilliance, clarity, anti-scratch properties, antistatic features or flame retardancy to optimize utility.

Flame retardants are prized in construction and electrical applications to prevent fire. They avert the start and spread of fires. Most plastics are inflammable, so fire resistance is added for safe usage in crucial industries like housing and electrical appliances.

Antistatic additives and agents prevent static charge buildup in plastics, while anti-scratch agents reduce scratch dimensions and visibility.

When rubbed against one another, plastic can become static and attract dust particles on its surface, which ruins its elegance and transparency. Antistatics interact with polymers to reduce surface charge buildup.

Some antistatic agents include quaternary ammonium salts, fatty acid esters, sulfonated wax, and ethylene oxide amine.

- Fillers

These common additives for plastic enhance properties and processability and reduce manufacturing costs. About 5% to 50% filler is added to different products depending on its type and the application of the manufactured good.

Inorganic plastic fillers and additives, such as calcium carbonate, aluminates, and graphite, and natural organic ones like coconut shell powder, cotton, and wood flour are frequently used.

- Antimicrobial Agents

Antimicrobial agents, as the name suggests, keep microorganisms like viruses, yeasts, fungi, and bacteria in check for some time and their effects can be either bacteriostatic or bactericidal.

Strong oxidizing agents and metal ions like copper, mercury, and silver are bactericidal whereas organic agents are bacteriostatic. Concentrations also matter with low concentrations showing bacteriostatic effects and high ones having bactericidal properties.

- Plasticizers

Polymers may differ in plasticity, i.e. their ability to be moulded and shaped. Plasticizers make products more flexible and softer. They’re added during manufacturing to meet certain end-product goals.

Plasticizers and polymers, such as Polyvinyl Chloride or PVC, should be miscible for ideal results. Common ones include sebacate esters, chlorinated paraffins, and benzene dicarboxylic acid esters

- Colorants

Colorants color plastics internally and are chemical compounds that can be dyes or pigments, each used for different polymers.

However, they must be compatible with the plastic, durable, and chemically stable to withstand harsh external conditions like extreme temperatures and environmental stresses during production.

There are two types of pigments. Inorganic pigments have high light and thermal stability but are weaker coloring agents than their organic counterparts.

The organic ones offer powerful and bright coloring with a full color spectrum. However, they’re not as heat and weather resistant or opaque as the organic pigments.

Optical brighteners and masterbatches are two examples of plastic colorants.

Choosing The Best Additives To Redesign Plastics

Not all additives can work with a given plastic. Understanding individual chemical properties is important to select the best one from the plastic additives market. To do so, three areas must be studied:

Compatibility

Additives must blend perfectly with the polymers without precipitation or separation. Therefore, choosing agents that are stable over time and compatible with a particular plastic can lead to efficient products.

Compatibility ranges differ from one additive to another and deviation can cause problems such as additive precipitation.

Adaptability

Polymers require different external conditions to be processed. For instance, if operations need lengthy intervals of high temperature, additives must endure without volatilizing or decomposing, and colorants mustn’t fade.

A polymer may necessitate several additives if it undergoes different procedures.

Quantity

Don’t use more additive than necessary. Conductive agents, coupling agents, and antistatic agents, for instance, produce no effect if a certain threshold is crossed. More antistatic additives become redundant if a surface discharge layer is already formed.

What Are The Pros And Cons Of Bio-Based Plastics And Additives For Reducing Plastic Pollution?

Bioplastics use bio-based polymers and offer a more environmentally friendly approach to using plastics in terms of production and longevity. With a promising future, they may transform our economic structures and make our processes sustainable.

However, they may impact agricultural productivity negatively and may be more expensive.

We at CFI Carbon Products care about Earth and want to shift gears to a greener industry. Our new formulation, Austin Black 325, is innovative and more profitable for your business and the world than carbon black.

Call us now to know why!