Plastic filler materials have evolved from simple cost-reducing additives to essential components driving innovation and sustainability in the plastics industry.

As we move towards 2025 and beyond, these filler materials are undergoing a transformative period, fueled by advancements in nanotechnology, the increasing availability of bio-based materials, and a growing global demand for high-performance, eco-conscious plastic products.

This article will provide you with an in-depth analysis of the evolving role of plastic fillers within the plastics industry, examining key trends, Success stories, challenges, and emerging opportunities that are shaping the future of the plastic industry.

The Expanding Role of Filler Materiels in The Plastic Industry

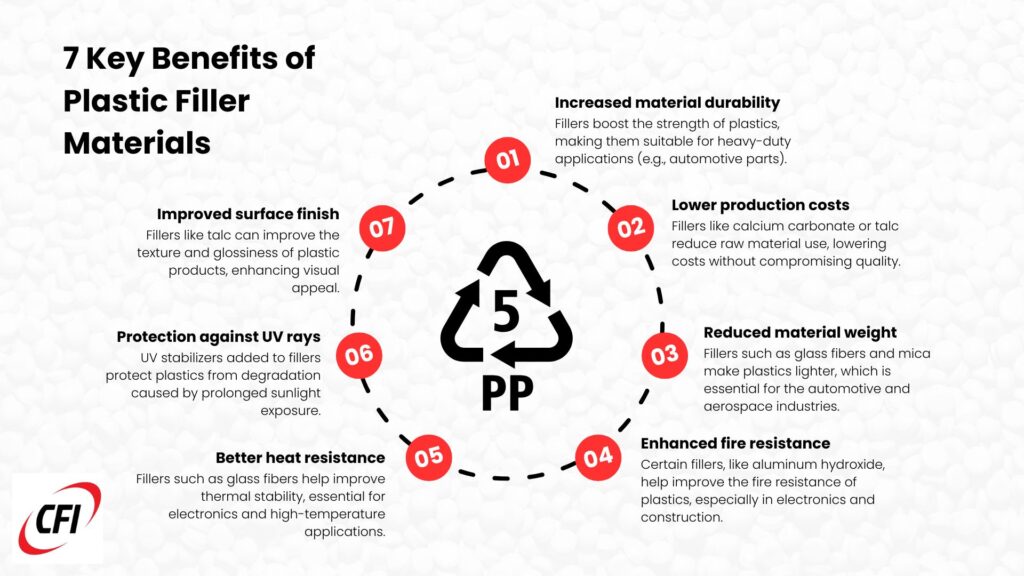

Plastic Material Fillers, incorporated into polymer resins, modify and enhance plastic properties, offering functionalities beyond mere cost reduction. They serve a multifaceted purpose:

- Mechanical Enhancement: Increase tensile strength, impact resistance, flexural modulus, and dimensional stability, allowing for thinner and lighter parts without compromising performance.

- Thermal Modification: Enhance heat deflection temperature, thermal conductivity, and flame retardancy, opening avenues for applications in demanding environments.

- Electrical Tailoring: Control electrical conductivity, ranging from anti-static properties in sensitive electronics to enhanced conductivity for EMI shielding or specific electrical applications.

- Optical Properties Control: Influence opacity, translucency, color, and surface finish, providing aesthetic and functional benefits.

- Boosting Sustainability: Facilitate the use of recycled plastic content and bio-based fillers, contributing to a circular economy and reducing environmental impact.

| Property | Filler Example | Benefit | Application |

| Tensile Strength | Glass Fiber | Increased load-bearing capacity | Automotive parts, structural components |

| Impact Resistance | Talc | Reduced breakage and cracking | Housings, appliances |

| Thermal Conductivity | Boron Nitride | Efficient heat dissipation | Electronic components, heat sinks |

| Flame Retardancy | Magnesium Hydroxide | Improved fire safety | Electrical enclosures, construction materials |

| Opacity | Titanium Dioxide | Enhanced color vibrancy, UV protection | Packaging, coatings |

Plastic Filler Materials Across the Plastic Industry Sectors: Applications, Trends & Success Stories:

The plastics industry’s diverse landscape, spanning packaging, consumer goods, automotive, and construction, relies heavily on tailored filler solutions to meet specific application requirements:

1. Packaging: The Sustainable Shift with Bio-Fillers

The packaging sector is experiencing a paradigm shift driven by consumer demand and stringent regulations concerning sustainability. Bio-based fillers are emerging as a pivotal element of this transformation.

| Bio-Filler | Source | Benefits | Applications |

| Wood Flour | Sawmill waste | Cost-effective, improved stiffness | Packaging containers, furniture |

| Starch | Corn, potatoes | Biodegradable, readily available | Loose-fill packaging, films |

| Cellulose Fibers | Wood pulp, recycled paper | Strength, moisture absorption control | Molded packaging, composites |

| Hemp Fibers | Hemp plant | High strength, lightweight | Reinforcements in composites, automotive interiors |

For More Information about Industry insights, Market Trends & sizes, and Future Outlook of Plastic Fillers, please read this article: Plastic Fillers: Applications, Markets, and Industry Insights in 2025

Case Study: Bio-Polymer Packaging Using Rice Hulls

A recent project involved creating biodegradable packaging from bio-polymers blended with rice hulls, an agricultural byproduct. This innovation not only addressed waste management by diverting rice hulls from landfills but also resulted in packaging that biodegrades within six months under soil conditions.

The composite material comprised a mix of polybutylene succinate (PBS), polybutylene adipate-co-terephthalate (PBAT), and rice hulls, achieving significant mechanical strength and environmental benefits. The formula, incorporating plasticizers and compatibilizers, was specifically tailored to enhance the blend’s durability

- Bio Polymer Trend Projection: Based on the current market trends and projections for bio-based fillers in food packaging, the demand for eco-friendly materials is strongly growing, fueled by stricter environmental regulations and rising consumer awareness about sustainability.

The global bioplastics market, which includes bio-based fillers, is expected to reach significant milestones, with a projected market size of $18.4 billion by 2025, growing at a compound annual growth rate (CAGR) of 19.5% leading into 2030.

2. Automotive: Driving Lightweighting with Advanced Fillers

Lightweighting is paramount in the automotive industry for improved fuel efficiency and reduced emissions. Filler materials play a critical role in achieving lightweight vehicles while maintaining structural integrity & performance.

| Material Filler | It Benefit | It Applications |

| Glass Fiber | High strength-to-weight ratio | Bumpers, dashboards, interior components |

| Carbon Fiber | Exceptional strength and stiffness | High-performance parts, body panels |

| Carbon Nanotubes | Enhanced electrical and thermal conductivity | Battery casings, structural composites |

| Talc | Improved dimensional stability and heat resistance | Interior parts, exterior trim |

Success Story: Revolutionizing Lightweight Design for Electric Vehicles

A groundbreaking achievement in lightweight vehicle design is showcased in the Revolution prototype, which reduced overall vehicle weight by 52% compared to a conventional design.

This was accomplished through the innovative use of carbon-fiber composites, aluminum, and thermoplastics. The vehicle’s body structure alone achieved a 60% mass reduction, enhancing fuel efficiency and range while maintaining structural integrity.

The prototype demonstrated zero tailpipe emissions, a 530-km range on hydrogen fuel, and the ability to accelerate from 0 to 100 km/h in just 8.3 seconds.

This holistic lightweight approach paved the way for cost-effective, sustainable electric vehicle production, showing a potential competitive edge over traditional SUVs like the Lexus RX300 and BMW X5.

The design integrated modular electronics and adaptable manufacturing systems, significantly simplifying production and reducing environmental impact.

The lightweight materials used not only minimized energy consumption but also extended the vehicle’s lifespan, demonstrating a sustainable and efficient alternative for the automotive industry.

3. Construction: Building a Sustainable Future with Durable Fillers

In construction, fillers contribute to the durability, weather resistance, and cost-effectiveness of plastic components.

| Filler | Benefit | Application |

| Calcium Carbonate | Increased stiffness, cost reduction | PVC pipes, window profiles |

| Talc | Improved impact resistance, weatherability | Roofing membranes, siding |

| Glass Fibers | Enhanced strength and durability | Composite decking, structural panels |

| Wood Flour | Cost reduction, improved aesthetics | Decking, fencing |

- Market Trend: The demand for recycled plastic lumber and composite materials in construction is anticipated to grow as sustainable building practices gain emphasis.

The global market for Wood Plastic Composites (WPC), which includes recycled plastic lumber, is projected to grow at a compound annual growth rate (CAGR) of over 5% from 2024 to 2029, driven by the push for eco-friendly materials.

This trend is supported by increased innovation in manufacturing and rising regulatory support for sustainability in construction

4. Consumer Goods: Enhancing Functionality and Aesthetics

Fillers in consumer goods improve product performance, durability, and appearance.

- Example: Mineral fillers in toothbrush handles provide better grip and weight, while titanium dioxide adds opacity and whiteness to plastic bottles.

- Plastic Filler Materials in Consumer Good Market Trends: Microplastics awareness is driving demand for eco-friendly personal care products. Companies are exploring bio-based alternatives like microbeads from agricultural waste (e.g., Bio-on’s sugar-waste beads used by Unilever) and biodegradable fillers such as soy or starch. This shift towards sustainable ingredients signals a united effort to combat plastic pollution.

Plastics Industry: How To Overcome Challenges in the Filler Landscape

| Challenge | Solutions |

| Fluctuating Raw Material Prices | Diversified sourcing, long-term supply contracts, development of alternative/synthetic materials |

| Environmental Impact | Increased use of recycled and bio-based fillers, closed-loop recycling systems, lifecycle assessments |

| Dispersion & Compatibility | Advanced compounding and processing techniques, surface treatment of fillers, compatibilizers |

| Performance Consistency | Stringent quality control measures, advanced characterization techniques, collaboration with filler suppliers |

Plastic Filler Materials Future Trends: Innovation and Sustainability at the Forefront

1) Hybrid Fillers

Hybrid fillers combine the advantages of different materials, achieving synergistic effects that enhance performance.

For example, glass fiber/wood flour hybrid fillers offer both added strength and sustainability, making them ideal for applications requiring a balance between reinforcement and eco-friendliness.

Smart Fillers

The integration of advanced functionalities into fillers, such as self-healing properties, pressure or temperature sensing, and antimicrobial qualities, is gaining momentum.

These smart fillers are reshaping industries by offering dynamic, responsive materials that can adapt to environmental changes or extend the lifespan of the product.

3D Printing with Advanced Fillers

As 3D printing evolves, fillers like carbon black are being utilized to enhance the properties of the printed materials.

These advanced fillers allow manufacturers to create complex geometries and customized parts with precisely controlled filler distribution, improving strength, durability, and functionality.

Austin Black 325

Austin Black 325 is an innovative filler material offering reduced CO2 emissions and superior performance. Derived from low-volatile bituminous coal, it not only reduces environmental impact but also delivers enhanced durability and UV protection for plastics.

This filler is particularly valuable in creating long-lasting, sustainable products in industries like automotive and outdoor equipment

.

Austin Black Eco

Building on the sustainability trend, Austin Black Eco is a carbon black alternative designed for eco-conscious manufacturing. It provides excellent reinforcement and UV stability while offering a reduced environmental footprint.

Ideal for products exposed to outdoor conditions, this filler is gaining traction for its green credentials without compromising on quality.

Conclusion: A Transformative Era for Plastic Filler Materials

Plastic fillers are central to the ongoing evolution of the plastics industry. Their expanded functionalities, combined with the increasing focus on sustainability and advanced manufacturing techniques, are poised to redefine the possibilities of plastic materials. By actively pursuing innovation, addressing existing challenges, and prioritizing sustainable practices, the plastics industry can unlock the full potential of plastic fillers, paving the way for a future of high-performance, eco-friendly, and cost-effective plastic solutions.