John Wesley Hyatt Synthetic introduced polymers in the market in the 19th century as a substitute for natural ivory. He made them by combining cotton fiber cellulose with camphor.

The discovery and production opened new doors for humanity as they could move beyond nature’s limits to create on a grand scale.

However, its use soon necessitated other molecules to modify the super industrial ingredient to better its performance and meet standards. This is where polymer additives come in.

They’re added to polymer matrices to make them more processible, thermally, electrically, and mechanically productive, and aesthetically appealing.

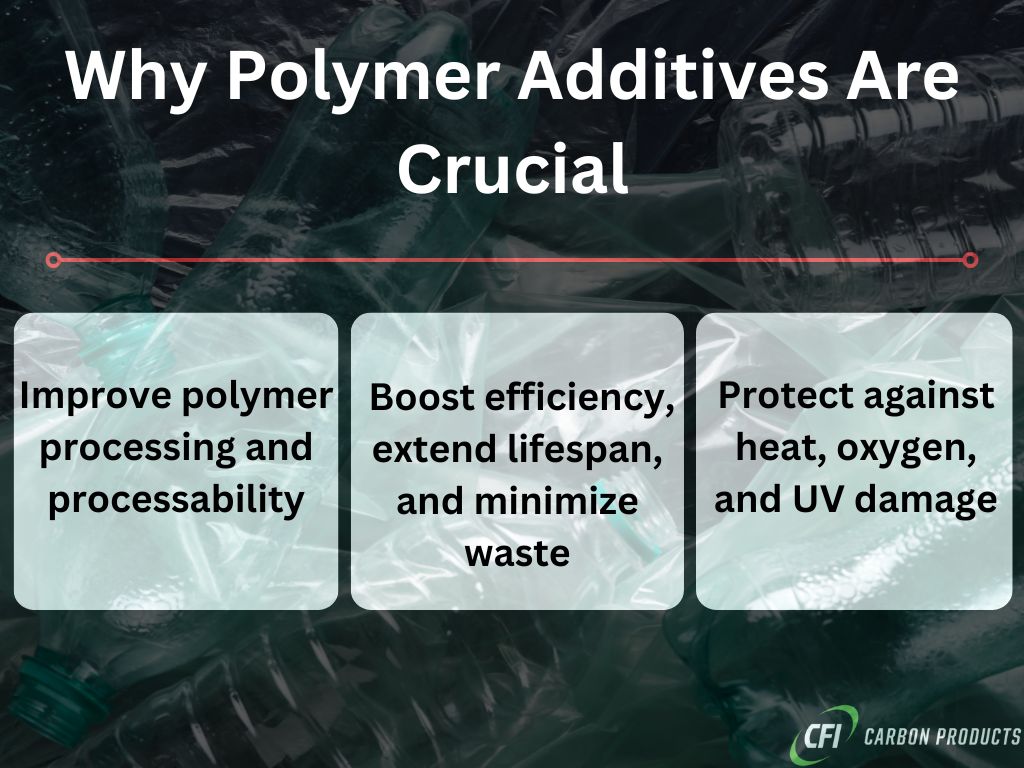

Why Polymer Additives Are Essential

Polymer additives enhance plastic performance and durability. Here are some reasons why polymer additives are crucial:

- They upgrade the polymer’s processing abilities and processability.

- They lower costs by improving efficiency, extending product lifespan, and reducing material waste.

- They extend product life by preventing degradation due to high temperatures and other external conditions, such as the oxygen and UV light, such as discoloration and brittleness.

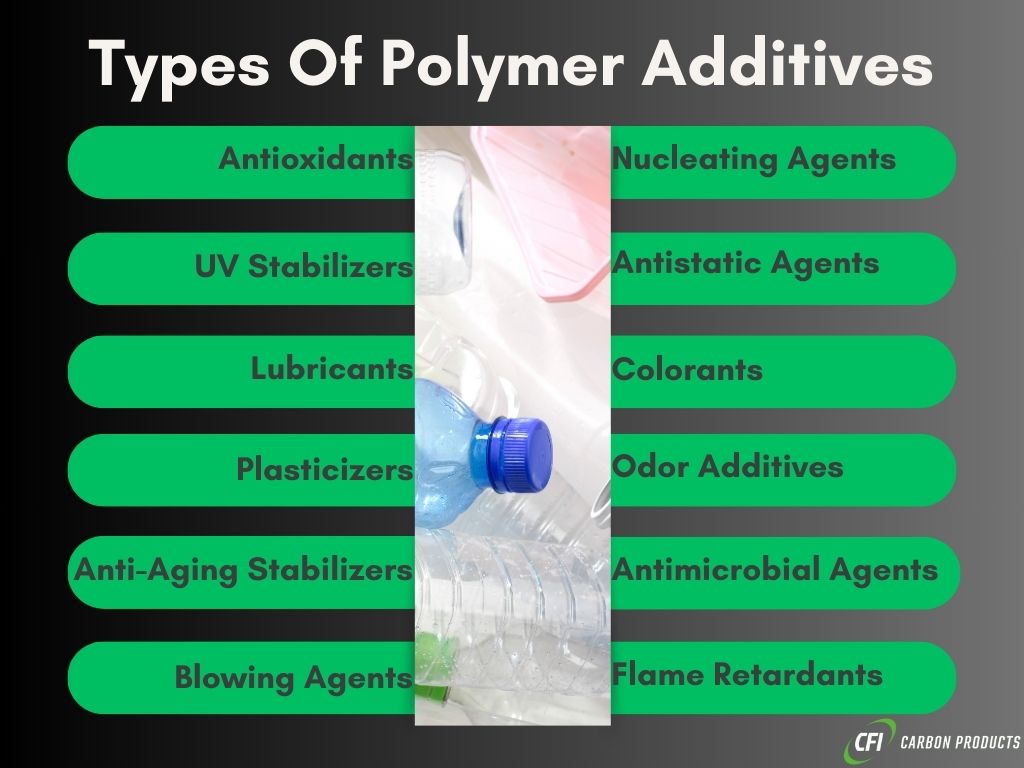

Types Of Polymer Additives And Their Uses

Luckily, we have many polymer additives at our disposal with traits giving products the necessary boost and prolonging their life. Here are the different types:

Antioxidants

Antioxidants work by inhibiting polymer degradation and oxidation by environmental factors such as heat, light, or mechanical stress. The two types include:

Primary Antioxidants

Primary antioxidants make plastics more thermally stable over the long term and more processible. They can work under different temperature ranges and neutralize damage causing free radicals during polymerization at the initial stages of oxidation.

Commonly used primary stabilizers hindered phenols, which are great at preserving polymers such as plastics and rubber.

In the food and beverage industry, for instance, these hindered phenols work their magic by preserving food, preventing spoilage, and keeping edibles like baked goods delicious and fresh for longer.

Secondary Antioxidants

Secondary antioxidants combine with the primary stabilizers and extend protection during the entire lifecycle of the product. They prevent oxidation by decomposing and neutralizing hydroperoxides, oxidative intermediates, to stop the oxidation chain reaction.

Phosphites, for instance, are used in PVCs to improve light and heat stability and mechanical integrity in products like pipes and flooring materials.

UV Stabilizers

UV rays come from the sun and artificial light sources like lamps and tanning beds. While the ozone layer hinders a significant amount of rays from entering our atmosphere, the shielding isn’t enough and sunlight can still damage products when exposed.

UV stabilizers are polymer shields against sunlight. They absorb and reflect it, thereby decreasing discoloration and degradation. They come in two types:

HALS Or Hindered Amine Light Stabilizers

HALS offer protection against photodegradation that reduces service life, mechanical property loss, discoloration, surface cracking and the inability to withstand harsh environmental conditions.

They capture and neutralize free radicals, thereby stopping harmful chain reactions.

You don’t need a high concentration to achieve the desired results because HALS are regenerated instead of consumed. They provide light and thermal stabilization in polyolefins.

UVAs Or Ultraviolet Light Absorbers

UVAs absorb harmful rays and dissipate them as thermal energy. They’re therefore great in plastic water bottles, packaging films, polyesters, or additives sensitive to sunlight like flame retardants and pigments.

Sometimes, multiple agents process the same polymer to achieve several benefits and uses.

Lubricants

Lubricants reduce polymer friction between chains (internal lubricants) and improve processing by ensuring smoother flow and reducing damage during molding and extrusion between the polymer and the equipment (external lubricants).

Common lubricants include fatty acids and esters. Fatty acids work primarily with extruded and rigid plastics.

Plasticizers

Plasticizers like phthalate esters increase polymer flexibility and workability in rigid plastics like polyvinyl chloride.

Anti-Aging Stabilizers

Anti-aging stabilizers prevent plastic degradation caused by environmental factors like heat, oxygen, UV radiation, and mechanical stress. Polymers can become brittle, discolored, or lose their mechanical properties without them.

Additives like stabilizers, antiozonants, and antioxidants fight against plastic deterioration and increase product life. This also helps reduce the negative environmental impact of rejected plastics.

Blowing Agents

Blowing agents produce foamed plastics by creating a cellular structure within the polymer by decomposing at a defined temperature. They decrease the density, enhance insulation, and improve impact resistance.

Blowing agents release gases that expand within the polymer matrix, forming tiny bubbles or cells. The type of gas and expansion process determines the final foam structure.

Flame Retardants

Flame retardants prevent fire in plastics, household appliances, textiles, and building materials.

Halogens like bromines and phosphorus-based chemicals are extensively used in polyolefins, polyester, and polyamides.

Bromine based fire retardants trap high-energy free radicals and stop exothermic processes. They’re also cost-effective and allow polymer property retention

Nucleating Agents

Nucleating agents are added to semi-crystalline polymers, such as polypropylene and polyethylene, to promote and control crystallization and improve mechanical properties, optical clarity, tensile strength, impact resistance, heat temperature distortion, surface gloss, rigidity, transparency, dimensional stability, and processing efficiency.

They are used in automotive, food electronics, and medical fields. Some common ones include:

- Inorganic agents like silica, clay, and talc that augment nucleation density and form scattered crystals in the matrix.

- Organic agents like benzoic acid derivatives, some organic salts, and sorbitol that increase and speed up polymer crystallization.

- Carbon based agents like graphene, carbon black, and carbon nanotubes that improve electrical, thermal, and mechanical properties.

Antistatic Agents

Antistatic agents reduce or eliminate static electricity buildup, increasing surface conductivity, allowing charge dissipation, and preventing dust attraction, sparks, or handling issues.

Due to their efficient performance and role, they’re used in many industries and products such as polymers, coatings, textiles, and packaging. Some great and highly used anti-static additives are ammonium compounds, polyethylene glycol esters, and amines.

Colorants

Colorants impart color to plastics, coatings, and other materials for aesthetic, functional, or branding purposes. They can be organic, inorganic, pigments, dyes, or masterbatches.

Odor Additives

Odor additives enhance, modify, or neutralize smells in plastic products and are sometimes essential to mask or eliminate smells that may generate during plastic processing from other additives like flame retardants, plasticizers, or polymers.

Masking fragrances are only a short-term solution since they wear off shortly.

Odor agents in consumer goods, packaging, automotive, and industrial applications improve user experience and address odor-related concerns.

Antimicrobial Agents

Antimicrobial agents in plastics and coatings inhibit the growth of bacteria, fungi, mold, and viruses. They increase product hygiene, longevity, and safety by preventing microbial contamination, odors, and degradation.

Medical technology such as implantable devices uses them to keep such equipment safe.

Are Polymers And Plastics The Same Thing?

Plastics are synthetic polymers that humans use for different processes and tasks. Polymers, however, can be man-made or naturally occurring. DNA is a natural polymer made of nucleotides.

While carbon black is a sought-after nucleating agent, we at CFI Carbon Products have transitioned to the new and improved Austin Black 325 because of its undeniable benefits. Talk to us if you want to know more!